Production

From an innovative implant idea to its perfect implantation, in accordance with the most stringent safety standards

IMPLANET has designed, manufactured and marketed spinal and orthopaedic implants for over 12 years.

Thanks to its multidisciplinary team with complementary skills and at the cutting edge of innovation, IMPLANET is present at every step of development, from the original concept to its manufacturing until bringing it to the market, supervising the entire manufacturing process.

All its products are 100% made in Europe.

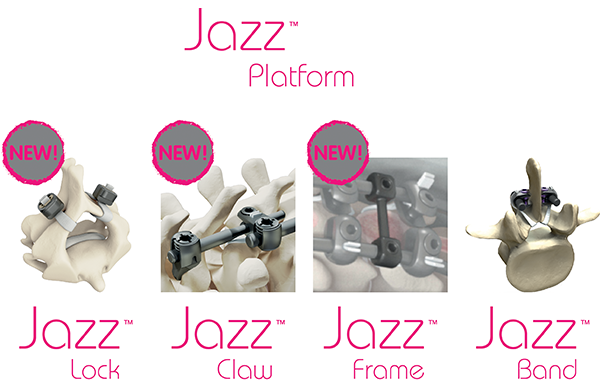

The mission of IMPLANET is to provide complete simple and reliable prosthetic solutions to all surgeons.

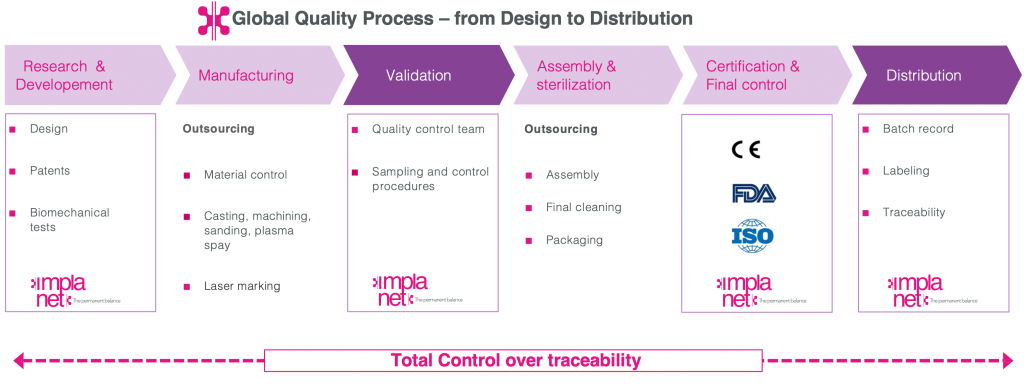

Sharing knowledge of each process stakeholders is the essence of the Research & Development of IMPLANET. The link between the demands expressed by the surgeons and IMPLANET’s own vision sector starts the creation process.

It always begins with design development exclusively conceived to serve the improvement of the implant both in terms of ease of use by the medical teams and performance for the patient’s benefits.

Once the design is validated by the expert surgeons and testing, IMPLANET launches the manufacturing process of the implants and instruments. The quality controls procedures are designed during the development process.

They are implanted at multiple points during the manufacturing as well as before assembly process and again at the very end after sterilization.

IMPLANET imposes itself these multiple quality controls with stringent specifications and quality system in order to deliver medical devices of uncompromised quality and security.